Other Hydroponic Growing Systems

The operating characteristics and requirements for most hydroponic growing systems are:

- inefficient in their use of water and reagents

- require electrical power

- require pumps of varying capacity

- require specialized equipment

- scheduling of nutrient solution delivery, requiring computer-generated schedules based on environmental conditions and stage of plant growth

Hydroponic growing systems are defined by how a nutrient solution is used:

- “open” system: nutrient solution is passed just one time through the plant root mass or rooting medium, and then discarded. A nutrient solution collection and disposal system is required

- “closed” system: nutrient solution, after passing through the plant root mass or rooting medium, is recovered for reuse. Before reuse, the nutrient solution will require filtering, sterilization, restoring to original volume, and pH and elemental content adjustment to their original levels.

Systems Not Requiring a Rooting Medium

(have limited commercial application)

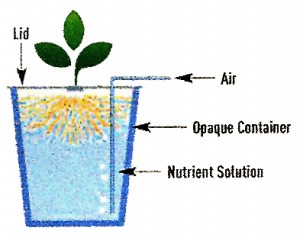

a. Standing-Aerated/Circulated Nutrient Solution

roots of the plant are suspended in a container filled with a continuously aerated nutrient solution – primarily used for plant nutrition studies (Figure 3)

Figure 3 Illustration of the standing-aerated hydroponic growing system. Plant roots are suspended in a continuously aerated nutrient solution.

Commercial Application:

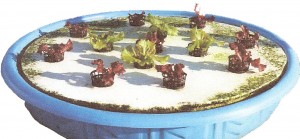

“Raft system,” for the production of lettuce and herbs (Figure 4). A flat shallow water-tight container is filled with nutrient solution, forming a pond, and a raft is then floated on that pond. The nutrient solution is kept aerated by constant movement, and/or air lines are placed in the bottom of the pond, bubbling air or oxygen (O2) up through the nutrient solution in order to maintain the desired O2level in the nutrient solution.

Figure 4 Lettuce being grown using the raft hydroponic growing system. Lettuce plants are fitted into openings in Styrofoam sheets being floated on a pool of nutrient solution.

The system can be used outdoors when rainfall events are infrequent and/or are of low amounts for any one event, and by a home gardener using a child’s plastic swimming pool, filling the pool with nutrient solution and floating a raft on the surface as shown in Figure 5.

Figure 5 Lettuce plants being grown on a raft floating on a nutrient solution in a child’s swimming pool.

Required Equipment:

- water tight rooting container

- stirring and/or aeration system in the nutrient solution rooting vessel or pool

- Styrofoam sheets as raft material

Advantages:

- easy to assemble and operate, minimum requirements for pumps, piping, and storage containers

- if plastic sheeting is used to form the nutrient solution pool, it can be either discarded after use, or cleaned and sterilized for the next crop

- fairly efficient in its use of water and reagents

- for raft material, a Styrofoam sheet is most suitable, being inexpensive and a durable substance that can be either discarded when the crop is harvested, or reused after sterilization

Disadvantages:

- limited to the growing of a single plant per vessel of sufficient size to accommodate the plant roots, requiring constant aeration and periodic replacement of the nutrient solution depending on the plant being grown and its growth rate

- nutrient solution bed must be level and water tight

- nutrient solution requires constant aeration and/or circulation to maintain the desired oxygen (O2) level

- nutrient solution composition will change with time, requiring replacement or adjustment to keep it at its original composition during the growth period of the plant

- raft growing system is only suitable for the production of short-stem plants and those that come to maturity is a short time period (30 to 45 days)

- once rafts are floated onto the nutrient solution pond, depending on the size of the pond, the crop may not be easily attended until harvest; therefore, this system is not suited for plants that require daily individual attention

- root disease is a constant threat, for with use, the nutrient solution becomes a brew for the growth of bacteria and fungi

- temperature control of the nutrient solution can pose a problem in environments that have widely varying air temperatures

- wasteful of water and reagents when the nutrient solution is eventually discarded, possibly requiring treatment as an environmental hazardous waste.

b. Nutrient Film Technique (NFT)

known by its acronym, NFT, plants, either rooted in a rockwool cube or block of similar stable rooting medium, are set in an enclosed sloping (2 to 3% slope) trough with a nutrient solution periodically introduced at the head of the trough that flows down the trough by gravity. The width, height and length of the trough are not set dimensions. Troughs can be made using a variety of materials: PVC gutters and pipes, plastic lined wood or metal constructed troughs, and even light-proof plastic sheeting. The material selected must be water proof, and the constructed trough must have sufficient strength to maintain its shape and be unbending (Figure 6).

Figure 6 An illustration of the Nutrient Film Technique (NFT) method for growing plants hydroponically. A nutrient solution is introduced at the head of the slopping trough, flowing down by gravity, to be collected and re-circulated. Plants, rooted in a stable medium, are appropriately spaced in the trough.

With each irrigation, sufficient nutrient solution must be discharged at the head of the trough so that there is an outflow at the end of the trough. The volume and timing of nutrient solution introduction is based either on a set time schedule, water needs of the plants, or scheduled by a computer-generated program based on inputs such as, environmental conditions, stage of plant growth, etc.

Advantages:

- relatively easy and inexpensive to set up

- well suited for the growing of lettuce (Figure 7)

- plastic sheeting can be used to construct a trough as long as it is placed on a firm unbending surface

Disadvantages:

- trough length and the volume of nutrient solution applied at each irrigation can be a factor affecting plant performance at the end of the trough due to changes in oxygen (O2) and elemental content of the flowing nutrient solution.

- retention of the applied nutrient solution in the root mass will adversely impact plant growth

- disease is a constant threat and may be difficult to control if occurring with long-term crops, such as tomato, cucumber and pepper

- when plant roots can eventually fill the trough, the flow of nutrient solution is impeded and the nutrient solution begins to flow over the top of the root mass

- Anaerobic conditions can develop within the root mass, resulting in root death and eventually the death of the plants

- NFT design and function characteristics have essentially limited its use for the growing of short-term crops, such as lettuce and herbs

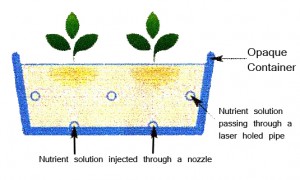

c. Aeroponics

Roots of the plant are suspended in an enclosed chamber, being either continuously or intermittently bathed with a spray or mist of nutrient solution. The rooting chamber can be a box, a teepee or lean-to structure with the plants placed on openings on the slanted sides with their roots suspended in the enclosure. Of all the hydroponic growing systems, it is the most novel, but has limited practical application. The finer the nutrient solution droplets, the greater will be the potential for adherence on the roots. High pressure pumps are required for dispensing the nutrient solution through the spray nozzles. In some system designs, a shallow pool of nutrient solution is allowed to form in the bottom of the rooting chamber so that a portion of the plant roots will lay in this pool that serves as a supply both needed water and nutrient elements, particularly when the atmospheric demand is high This hydroponic method of growing is illustrated in Figure 8.

Figure 8 An illustration of the aeroponic hydroponic growing system. Plant roots, suspended in an enclosed container, are either continuously or intermittently bathed with a nutrient solution.

Advantages:

- easy and inexpensive to construct the root chamber which can have various designs, depending on the plant species being grown and desired outcome

- well suited for the growing of small plants, such as lettuce and herbs, particularly for those herbs whose roots are the harvested plant part

- method stimulates root initiation and growth, making this an excellent method for generating roots for those plant species difficult to root from stem cuttings

Disadvantages:

- nutrient solution must be filtered to remove suspended materials that can clog nozzle openings

- size of the nozzle openings will determine droplet size; the smaller the openings, the greater the pump pressure required to discharge the nutrient solution

- under high atmospheric demand conditions, this system of water supply may not be sufficient to meet the plant’s water needs, resulting in plant wilting

- significant danger for root disease occurrence due to the high atmospheric humidity conditions within the rooting chamber

Systems Requiring a Rooting Medium

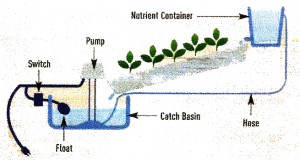

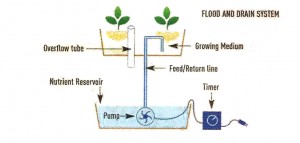

a. Flood-and-Drain (also referred to as Ebb-and-Flow)

A nutrient solution is pumped from a storage vessel into the base of the rooting vessel, flooding the vessel. After several minutes, the nutrient solution flows back by gravity into the storage vessel. An illustration of the basic design for a flood-and-drain system is shown in Figure 9.

Figure 9 An illustration of the flood-and-drain hydroponic growing system. By pumping from a storage tank, the nutrient solution periodically floods the rooting medium bed for a short period of time with the nutrient solution draining back into the nutrient solution storage tank by gravity.

The rooting medium must be free from soil and colloidal organic and inorganic materials and of sufficient volume-weight to remain in place when flooded with nutrient solution. Pea gravel is a suitable rooting medium. The rooting medium water-holding capacity has two conflicting outcomes. On one hand, high retention allows for longer periods between irrigations, but on the other hand, this allows for the accumulation of “salts” and/or formation of precipitates that will, in time, adversely affect the nutritional status of the growing plants. During the growing period, the rooting medium may require periodic water leaching to remove accumulated “salts.” Monitoring the electrical conductivity (EC) of the returning nutrient solution, or by drawing an aliquot of retained nutrient solution in the rooting medium can be used as a means to determine when water leaching is required.

Advantages:

- relatively easy to construct and operate with the rooting bed constructed using water-resistant materials

- rooting bed can vary in size based on number of plants

- suitable for both large and small scale plant production systems

- suitable for outdoor use

Disadvantages:

- volume weight of the rooting medium (pea gravel) requires the construction of sturdy rooting vessel and supports

- clean, element- and colloidal-free pea-gravel is difficult to find, and if prepared by the grower, requires the use of strong acids and acid-resistant washing facilities

- large rooting beds require high capacity pumps to quickly move the nutrient solution from the storage tank to flood the rooting bed

- timing for each irrigation requires a means for determining the water needs of the plants as well as a system for the nutrient element monitoring of the nutrient solution and plants

- with accumulation of “salts” in the rooting medium, water leaching will be required that is costly in terms of amount of water required and a suitable means for collecting the leachate for proper disposal

- wasteful of water and reagents when the nutrient solution is discarded. Disposal procedures are also required if designated as a “hazardous waste”

- with re-circulation of the nutrient solution, volume adjustment is required with the pH and level of essential elements monitored to determine when adjustment is needed in order to maintain initial composition and avoid plant element insufficiencies

- to prevent the occurrence of root disease, both filtering to remove suspended materials and sterilization are required for the re-circulated nutrient solution

- eventually precipitates of calcium sulfate and phosphate will form, providing another nutrient element source for plants, creating the potential for the occurrence of plant nutrient element insufficiencies

- precipitates are not removed from the rooting medium by water leaching

- when the rooting medium is reused, removal of accumulated precipitates and root debris will require acid washing and steam sterilization

b. Drip Irrigation

Most widely used commercial hydroponic method for the growing of tomato, cucumber, and pepper. Nutrient solution is delivered at the base of the plant rooted in either bags or pots containing either an inorganic (perlite, rockwool, volcanic rook) or organic (peat, pinebark, core) media, or with the use of rockwool or coir slabs. The characteristics of the drip delivery system will be determined by the number of discharge points as well as the size and flow rates of drippers (Figure 10).

Figure 10 Photograph shows drippers placed at the base of tomato plants rooted in rockwool blocks set on rockwool slabs. Delivering nutrient solution to each individual dripper is a nutrient solution supply line (PVC white pipe) that is shown lying at the base of the structure holding the rockwool slabs.

For all drip irrigation systems, the flow rate and volume of nutrient solution applied will depend on the water demand of the plants. Plant species, stage of growth, and frequency and volume of nutrient solution delivered with each irrigation are factors that will determine the elemental content of the delivered nutrient solution, requiring skill and experience in order to establish these factors. For better nutritional control, the nutrient solution is delivered only periodically during the day, the schedule depending on an established nutritional plant program for the plant species being grown, its stage of growth, and then only water when needed to keep the plants in a turgid state. Sufficient nutrient solution or water should be delivered with each irrigation so that there is a slight outflow at the base of the rooting vessel or slab, requiring a means to collect and dispose the effluent. The volume and rate of flow from a dripper will determine the distribution of nutrient solution and water within the rooting medium.

With time, there occurs a retention and accumulation of unused nutrient solution in the rooting medium requiring electrical conductivity (EC) monitoring. Depending on the physio-chemical characteristics of the rooting medium and plant species being grown, the rooting medium will require water leaching when the retained nutrient solution reaches a certain EC level.

Figure 11 A tower hydroponic growing system consisting of a stack of Styrofoam buckets set a 90 degree angle with each other, the opening space in each bucket planted to lettuce. Nutrient solution is introduced at the top of the stack, flowing down the tower by gravity.

Another form of this method places plants in the corners of buckets, stacked at a 90 degree angle from each other forming a tower as shown in Figure 11, or the tower can be a large diameter plastic pipe with openings in the sides sufficient in size to accommodate the plant being grown. Access pockets are spaced necessary to accommodate the plant species being grown, such as flowers, ornamental plants, lettuce, herbs, strawberries, and even tomato, pepper, and vine crops. A nutrient solution is introduced at the top of the tower that flows down through the rooting medium by gravity, the volume and timing sufficient to provide the required water and essential plant elements for all the plants in each bucket that forms the tower. Usually sufficient nutrient solution and/or water is applied at the top of the tower so that with each irrigation, there is an outflow at the base of the tower. With some designs, drippers are placed at each plant position in the tower to ensure sufficiency in water and essential element availability. With both methods of nutrient solution/water delivery, the irrigation schedule, flow rate and volume must be sufficient to meet plant water demand.

The outflow of nutrient solution at the base of the tower is either discarded or collected for reuse. With re-circulation of the nutrient solution, its pH and level of essential elements require monitoring to determine what adjustments and replacements are necessary to maintain its desired properties. Filtering is also required to remove suspended materials and sterilization to prevent root disease occurrence. Towers conserve space by allowing for large numbers of plants to be grown in a confined area.

Advantages:

- system reliable in terms of plant performance.

- method fairly efficient in its use of water and reagents, even when operated as an “open” hydroponic system

Disadvantages:

- drippers require constant monitoring to ensure consistent flow of nutrient solution.

- injection pumps for generating the applied nutrient solution require periodic inspection and adjustment.

- timing schedule and volume of nutrient solution delivered can significantly affect plant growth, therefore requiring skill and experience to determine that required to supply sufficient water and plant nutrient elements.

- usually sufficient nutrient solution is delivered with each irrigation so that there is a slight outflow at the base of the rooting vessel or slab, requiring a means to collect and dispose the effluent.

- elemental accumulation of retained nutrient solution in the rooting medium occurs that begins to impact the nutritional status of the plants.

- electrical conductivity (EC) determination of either the outflow or retained nutrient solution in the rooting medium is required. Water-leaching of the rooting medium is required when the EC exceeds a certain level.

- water-leaching is costly in terms of amount of water required and the collection and containment of the leachate for proper disposal.

- eventually precipitates of calcium sulfate and phosphate will form, providing another nutrient element source for plants, creating the potential for the occurrence of plant nutrient element insufficiencies.

- precipitates are not removed by water leaching.

- rooting media is normally discarded after one use.

- for tower systems where the nutrient solution is introduced at the top of the tower, the nutrient solution changes in elemental and oxygen (O2) contents as its flows down the column. The plants at the base of the tower, therefore, grow slower, and possibly suffer from both O2 and elemental stress.

- towers require periodic rotation so that all the plants receive equal sunlight exposure